How to Make Hooks Using 3D Printing

To make hooks using 3D printing, first, choose a design that balances aesthetics and functionality. Select suitable materials like PLA for lightweight hooks or ABS for strength. Prepare your model, ensuring it’s compatible with slicing software, and set your printer with correct parameters based on your filament. Print your hooks while ensuring quality and finish them for improved aesthetics. If you follow these steps, you’ll create custom, innovative hooks tailored to your needs. Discover more about each process in detail.

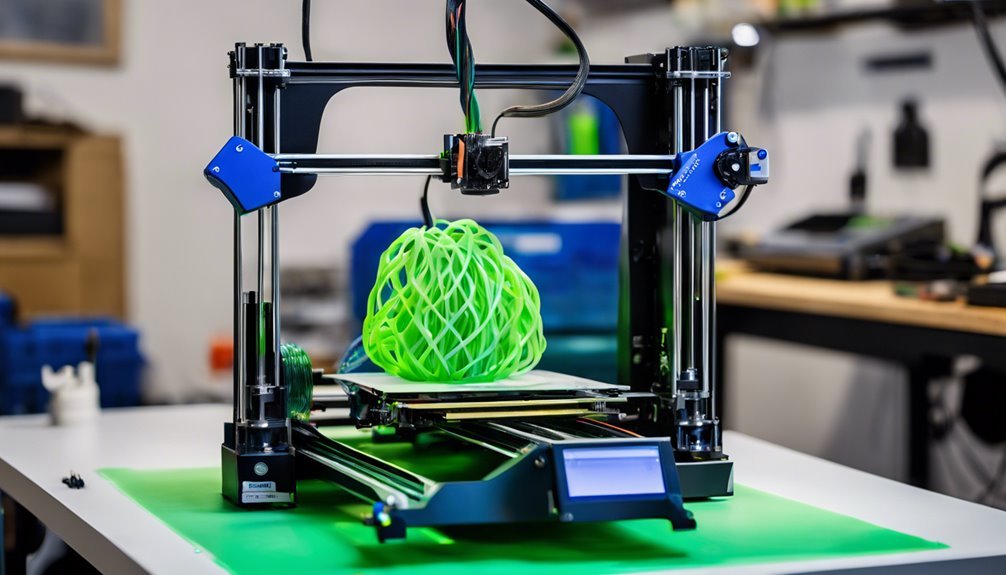

Understanding 3D Printing Technology

While you may be familiar with the concept of 3D printing, understanding its underlying technology is essential for effectively creating custom hooks. At its core, additive manufacturing employs various printing techniques to build objects layer by layer. This process allows you to design intricate geometries that traditional manufacturing methods often can’t achieve. Familiarize yourself with methods like Fused Deposition Modeling (FDM) and Stereolithography (SLA), as they each offer unique benefits for different materials and applications. Knowing how to manipulate filament properties or resin characteristics will enable you to craft hooks tailored to your specific needs. Embracing this technology not only fosters creativity but also empowers you to break free from conventional constraints, revealing endless possibilities in your custom hook designs.

Choosing the Right Hook Design

Once you’re familiar with the nuances of 3D printing technology, the next step is selecting the right hook design for your project. You’ll want to balance design aesthetics with functional requirements to guarantee your hook serves its purpose effectively while looking good. Consider the environment where you’ll use it; whether it’s for indoor organization or outdoor applications, the design must suit those needs. Pay attention to dimensions, load capacity, and attachment methods. Explore various geometries and styles to find one that resonates with your vision—after all, the freedom to innovate is one of 3D printing’s greatest advantages. Ultimately, your hook design should reflect a perfect marriage of form and function, enhancing both utility and visual appeal.

Selecting Suitable Materials for 3D Printing

Selecting the right materials for your 3D printed hooks is essential, as it directly impacts their durability, functionality, and appearance. You’ll want to evaluate various filament types, each with unique material properties. For instance, PLA offers ease of use and good surface finish, making it ideal for lightweight hooks. However, if you need something more robust, ABS or PETG might be your go-to, as they provide superior strength and heat resistance. Nylon is another option, known for its flexibility and durability, perfect for heavy-duty applications. By understanding these filament types and their material properties, you can make informed decisions that empower your creative freedom while ensuring your hooks perform effectively in their intended roles.

Preparing Your 3D Model

When preparing your 3D model for hook printing, start by selecting a design that meets your functional needs. Confirm your file format is compatible with your slicing software, as this can impact the printing process. Finally, pay close attention to sizing and dimensions to assure ideal performance and fit for your intended application.

Choosing Hook Design

As you commence on preparing your 3D model for hook design, it is essential to contemplate both functionality and aesthetics. Consider the design aesthetics that will complement your project while also meeting the functional requirements of your hook. You’ll want to guarantee that the hook is not only visually appealing but also capable of performing its intended task effectively.

Evaluate the dimensions and geometry to optimize strength and usability. For instance, a curved design might enhance grip, while a minimalist approach could reduce material usage without compromising integrity. Remember, innovative designs often arise from blending these elements creatively. By prioritizing both aesthetics and functionality, you’ll create a hook that embodies your vision and serves its purpose flawlessly.

File Format Considerations

To guarantee your 3D model is compatible with the printing process, it is crucial to take into account the appropriate file formats. The most common formats used in 3D printing are STL files and OBJ formats. STL files are widely accepted by various slicers and are perfect for representing your model’s geometry in a straightforward manner. They simplify the design while maintaining necessary details. On the other hand, OBJ formats can hold additional information, such as color and texture, making them ideal for more complex designs. Choosing the right format depends on your specific requirements, so consider your printer’s capabilities and the desired outcome. By selecting the correct file type, you empower your creativity while ensuring a successful print.

Sizing and Dimensions

Getting the sizing and dimensions right is essential for ensuring your 3D printed hooks function as intended. Follow these sizing guidelines to achieve ideal hook dimensions:

- Determine the weight capacity required for your hook.

- Measure the space where the hook will be installed.

- Consider the thickness of materials the hook will support.

- Adjust the hook’s depth for ideal functionality.

- Factor in the printing tolerances of your 3D printer.

Setting Up the 3D Printer

Before diving into the 3D printing process, it’s essential to guarantee your printer is properly set up and calibrated. Start with printer calibration; this verifies your extruder is delivering the right amount of filament. Use calibration cubes to check accuracy in dimensions. Next, focus on bed leveling, as a well-leveled print bed is important for adhesion and precision. Adjust the bed height to confirm it’s uniform across all corners, using a piece of paper to gauge the distance. After these adjustments, run a test print to validate everything’s aligned. This careful preparation will empower you to achieve high-quality prints, allowing you the freedom to create custom hooks without frustration or failure. Your setup lays the foundation for successful 3D printing.

Printing Your Custom Hooks

Start the printing process by carefully selecting the right filament for your custom hooks, as this choice markedly impacts strength and durability. You’ll find various customization options that suit your design inspiration and functional needs.

Consider these factors when choosing your filament:

- Material type: PLA, ABS, or PETG

- Tensile strength: Verify it meets your load requirements

- Temperature resistance: Match it to your environment

- Flexibility: Determine if you need rigid or pliable hooks

- Color options: Personalize your hooks to fit your style

Once you’ve selected your filament, set your printer parameters according to the material specifications. This attention to detail will yield high-quality, functional hooks tailored to your unique vision.

Finishing and Installing Your Hooks

Although you’ve successfully printed your custom hooks, the finishing touches and installation process are essential for ensuring their functionality and longevity. Start with surface preparation; sand any rough edges to enhance adhesion and aesthetics. If your hooks are to be painted or coated, apply a primer that suits your chosen finish.

During hook installation, use appropriate fasteners for the material you’re attaching to, ensuring they’re rated for the weight your hooks will bear. It’s wise to pre-drill holes to prevent cracking, especially in wood or drywall. For extra security, consider using wall anchors. Once installed, test the hooks’ stability by applying gradual pressure. This approach guarantees not only a strong hold but also your newfound freedom in organizing your space.

References

- https://en.wikipedia.org/wiki/3D_printing

- https://www.sciencedirect.com/topics/engineering/3d-printing

- https://www.nasa.gov/feature/nasa-uses-3d-printing-to-create-tools-and-parts

- https://www.mit.edu/

- https://www.thingiverse.com/

- https://www.researchgate.net/publication/328135952_3D_Printing_in_Product_Development

- https://www.3dprintingmedia.network/

- https://www.american3dprinting.org/

- https://www.formlabs.com/blog/3d-printing-hooks/

- https://www.nist.gov/news-events/news/2020/07/3d-printing-technology-opens-new-doors-manufacturing