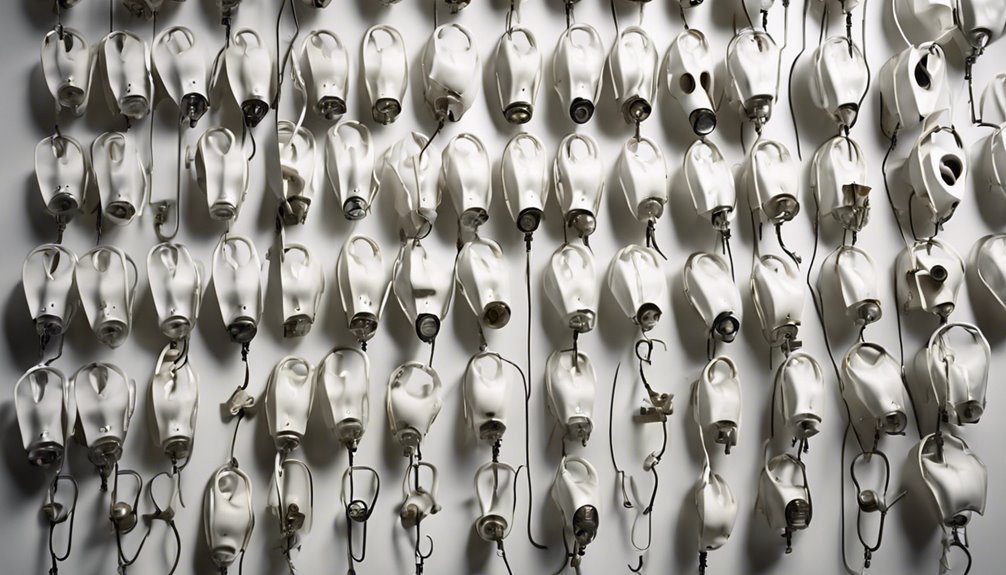

Hooks for Securing Gas Masks and Biohazard Suits

To secure gas masks and biohazard suits effectively, choose hooks that fit your environment and gear specifications. Wall-mounted hooks provide sturdy access, while magnetic hooks are flexible for metal surfaces. Overhead hooks maximize vertical storage, keeping gear off the ground. It’s essential to take into account weight capacity and material durability. Proper storage not only maintains gear readiness but also enhances safety. Explore best practices for maintaining both your hooks and safety equipment to guarantee peak performance during emergencies.

Understanding the Importance of Proper Storage

Proper storage of gas masks and biohazard suits is essential, not only for maintaining their functionality but also for guaranteeing your safety in emergencies. Effective storage techniques involve keeping these safety equipment items in a cool, dry place, away from direct sunlight and extreme temperatures that could degrade materials. Use airtight containers to prevent contamination and damage, and guarantee the items are clean before storage. Regularly inspect your equipment for wear and tear, as even minor damage can compromise your protection. Label storage areas clearly to facilitate quick access during emergencies. By following these guidelines, you’ll maximize the lifespan and reliability of your gas masks and biohazard suits, empowering you to respond effectively in critical situations.

Types of Hooks for Gas Masks

After ensuring ideal storage conditions for your gas masks, it’s important to reflect on how to secure them effectively when not in use. The right hook designs and mounting options can make all the difference in accessibility and safety. Here are three types of hooks to evaluate:

- Wall-Mounted Hooks: These provide a permanent solution, keeping masks easily reachable.

- Magnetic Hooks: Ideal for metallic surfaces, allowing for quick attachment and removal.

- Suction Cup Hooks: Perfect for smooth surfaces, offering flexibility without permanent installation.

Each option caters to different needs, ensuring your gas masks are not just stored, but also ready for immediate use. Choose wisely to enhance both your preparedness and your freedom.

Types of Hooks for Biohazard Suits

When storing biohazard suits, selecting the right hook type can greatly enhance your efficiency and safety. There are several biohazard suit hooks designed specifically for effective storage solutions. Wall-mounted hooks provide a sturdy option, allowing for easy access while keeping suits off the ground. Overhead hooks are ideal for maximizing vertical space and can be used in tandem with pulleys for effortless retrieval. Magnetic hooks are another innovative solution, offering flexibility for metal surfaces and preventing damage to fabric. Finally, adjustable hooks can accommodate various suit sizes, ensuring a snug fit. Choosing the right hook not only streamlines your storage process but also maintains the integrity of your biohazard suits, keeping them ready for use when needed.

Benefits of Using Hooks for Equipment Organization

Using hooks for equipment organization can greatly improve space management in your storage areas. By efficiently utilizing vertical space, you can keep your gas masks and biohazard suits neatly arranged and readily accessible. This not only streamlines your workflow but also enhances safety by ensuring that essential gear is easy to find when needed.

Improved Space Management

Effective space management is essential in environments where gas masks and biohazard suits are crucial. Utilizing hooks for equipment organization can greatly enhance your operational efficiency through space optimization. Here are three key benefits:

- Maximized Vertical Storage: By hanging gear, you free up valuable floor space, allowing for a more organized work area.

- Reduced Clutter: Hooks help eliminate disarray, making it easier to locate and manage your equipment efficiently.

- Improved Safety: Keeping gear off the ground minimizes tripping hazards, enhancing safety for personnel in critical situations.

Incorporating hooks not only streamlines your storage solution but also empowers you to maintain a functional environment, fostering a sense of freedom and readiness in emergency preparedness.

Enhanced Equipment Accessibility

Although maintaining a well-organized workspace may seem secondary in high-pressure environments, enhanced equipment accessibility is essential for swift response times. Using hooks for securing gas masks and biohazard suits promotes user-friendly designs that simplify access during emergencies. When every second counts, these solutions guarantee that your gear is easy to find and grab.

Moreover, efficient storage of essential equipment minimizes clutter, allowing you to focus on the task at hand. Hooks can be strategically placed to optimize workflow and reduce the time spent searching for critical items. This level of organization not only enhances the speed of response but also contributes to overall safety. By prioritizing accessibility, you empower yourself to act decisively when it matters most.

Factors to Consider When Choosing Hooks

When choosing hooks for gas masks and biohazard suits, you need to take into account weight capacity requirements to guarantee they can safely support the equipment. Additionally, material durability is essential, as the hooks must withstand harsh environments without degrading. Evaluating these factors will help you select the most reliable hooks for your needs.

Weight Capacity Requirements

Choosing the right hooks for gas masks and biohazard suits hinges considerably on weight capacity requirements. Understanding the weight limits is vital to guarantee both functionality and safety. Here are three key factors to take into account:

- Total Weight: Assess the combined weight of your gear to choose hooks that can support it.

- Safety Standards: Confirm hooks meet industry safety standards to prevent failures during use.

- Usage Frequency: Reflect on how often you’ll be using the hooks; higher frequency may necessitate stronger options.

Material Durability Considerations

After establishing the weight capacity requirements for your hooks, it’s important to contemplate the material durability. When selecting hooks, consider the material strength, as it directly impacts the hook’s ability to withstand loads without deformation. Materials like stainless steel or reinforced polymers often provide superior durability, resisting bending and breaking under stress. Additionally, evaluate environmental resistance; hooks should endure various conditions, like moisture, extreme temperatures, and chemical exposure, without degrading. For instance, hooks made from corrosion-resistant materials are ideal for humid or chemical-laden environments. By prioritizing these factors, you can guarantee your hooks not only support your gas masks and biohazard suits effectively but also maintain their integrity over time, providing you with the reliability you need.

Best Practices for Securing Safety Equipment

Securing safety equipment like gas masks and biohazard suits is essential for effective emergency preparedness. When you’re ready to protect yourself and others, follow these best practices:

- Designate Storage Locations: Verify your safety gear is stored in a specific, easily accessible location. This minimizes delays during emergencies.

- Use Quality Hooks: Invest in durable hooks designed for your safety gear. They should support the weight and allow for quick retrieval.

- Regular Inspections: Frequently check both the equipment and the hooks for wear and tear. Replace any damaged items promptly to maintain readiness.

Maintenance Tips for Hooks and Safety Gear

Maintaining your hooks and safety gear is essential to ensuring they function effectively when you need them most. Start by establishing regular maintenance routines that include thorough hook inspections at least once a month. Check for any signs of wear, corrosion, or damage that could compromise their strength. Clean hooks with a mild detergent and dry them completely to prevent rust. For your safety gear, inspect seams, zippers, and seals for integrity, replacing any worn components promptly. Store all equipment in a cool, dry place to prolong its lifespan. By adhering to these practices, you’ll enhance the reliability of your safety gear, ensuring you’re always prepared for any situation that demands your freedom and protection.

References

- https://www.cdc.gov/niosh/topics/respirators/default.html

- https://www.osha.gov/SLTC/respirators/

- https://www.epa.gov/emergency-response/chemical-biodefense

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6506177/

- https://www.who.int/health-topics/biosafety-and-biosecurity#tab=tab_1

- https://www.fema.gov/emergency-managers/national-preparedness/plan

- https://www.nist.gov/subjects/biosafety-and-biosecurity

- https://www.jstor.org/stable/10.5325/jpestudieduc.9.1.0001

- https://www.sciencedirect.com/topics/earth-and-planetary-sciences/personal-protective-equipment