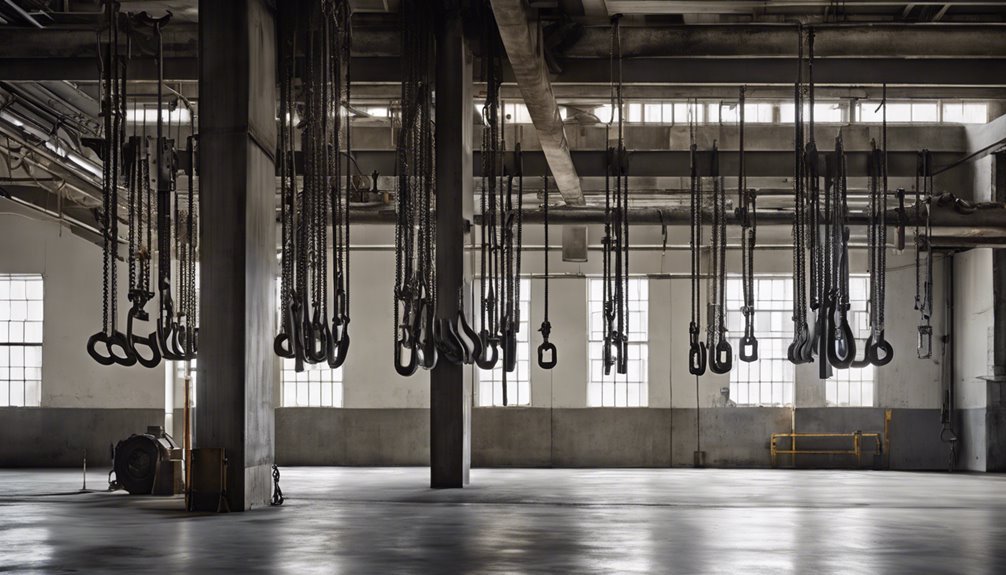

Heavy-Duty Hooks for Hanging Machinery Parts

Heavy-duty hooks are vital for securely hanging machinery parts in demanding environments. They enhance organization and safety while improving overall workspace efficiency. With various types like S-hooks and J-hooks, you can select the right fit for your needs. Consider weight capacity and load ratings to guarantee safety and reliability. Proper installation and maintenance are essential for peak performance. For a deeper understanding of specific requirements and best practices, you’ll find valuable information ahead.

Benefits of Using Heavy-Duty Hooks

When you consider the demanding environments of machinery maintenance and storage, using heavy-duty hooks can greatly enhance your operations. These robust fixtures are essential for heavy-duty applications, allowing you to securely suspend and organize machinery parts. This not only optimizes your workspace but also improves industrial efficiency by minimizing clutter and maximizing accessibility. By employing heavy-duty hooks, you’re investing in safety, as they reduce the risk of equipment damage or accidents due to improper storage. Additionally, their durability guarantees they withstand the rigors of daily use, making them a reliable choice for your maintenance requirements. Ultimately, leveraging these hooks can free up valuable time and resources, empowering you to focus on core tasks while maintaining a streamlined operation.

Types of Heavy-Duty Hooks

Heavy-duty hooks come in various types, each designed to meet specific needs in machinery maintenance and storage. Understanding these types can help you choose the right hook for your industrial applications.

- S-Hooks: Versatile and easy to use for hanging items.

- J-Hooks: Ideal for securing cables or hoses.

- Swivel Hooks: Allow for rotation, making them great for dynamic environments.

- Eye Hooks: Perfect for lifting and rigging tasks.

These hooks are made from different hook materials, ensuring durability and strength. By selecting the appropriate type, you can enhance safety and efficiency in your workspace. Remember, the right heavy-duty hook can make all the difference in organizing and maintaining your machinery parts effectively.

Material Considerations for Heavy-Duty Hooks

When selecting heavy-duty hooks for machinery parts, you need to take into account material strength and durability to guarantee they can withstand significant loads. Corrosion resistance is also essential, especially in environments where exposure to moisture or chemicals is common. Finally, understanding the weight capacity of different materials will help you choose hooks that meet your specific application requirements.

Material Strength and Durability

The effectiveness of heavy-duty hooks hinges on their material strength and durability, which are critical for safely supporting substantial machinery parts. You need to verify that the materials used have undergone rigorous material testing and load analysis to guarantee their reliability under stress.

Consider these key factors:

- Tensile Strength: Ability to withstand pulling forces without breaking.

- Fatigue Resistance: Endurance against repeated loading cycles.

- Impact Toughness: Capacity to absorb energy during sudden loads.

- Weight-to-Strength Ratio: Balance between heaviness and load-bearing capability.

Choosing the right material not only enhances performance but also verifies longevity in demanding environments. This knowledge empowers you to make informed decisions, giving you the freedom to optimize your setup effectively.

Corrosion Resistance Options

While selecting heavy-duty hooks for machinery, considering corrosion resistance is essential, especially in harsh environments where exposure to moisture and chemicals is common. You’ll want to explore various corrosion prevention techniques to prolong the hooks’ lifespan. Stainless steel is a popular choice due to its natural resistance, but if you’re looking for alternatives, consider hooks made from carbon steel with protective coatings options. These coatings—like powder coating or galvanization—offer an additional barrier against corrosion. Regular maintenance and inspection can also enhance longevity, helping you avoid costly replacements. By understanding these materials and techniques, you can guarantee your heavy-duty hooks stand up to the challenges of your specific environment, providing reliability and freedom in your operations.

Weight Capacity Considerations

Selecting heavy-duty hooks involves not just corrosion resistance but also understanding their weight capacity. You need to evaluate how much weight each hook can handle and ascertain proper weight distribution to avoid failure. Always perform load testing to guarantee safety and reliability.

- Assess the hook’s material; steel offers superior strength.

- Check the manufacturer’s specifications for maximum load limits.

- Take into account the shape of the hook for ideal weight distribution.

- Regularly inspect the hooks to prevent fatigue and wear.

Weight Capacity and Load Ratings

Understanding weight capacity and load ratings is essential when choosing heavy-duty hooks for hanging machinery parts. It’s critical to evaluate the maximum weight each hook can support, which is determined through rigorous load testing. These ratings guarantee safety and functionality, preventing accidents caused by overloading. Furthermore, proper weight distribution is fundamental; uneven loads can compromise the integrity of the hook and the entire setup. Always refer to manufacturer specifications for load ratings, keeping in mind that environmental factors might affect performance. By prioritizing these considerations, you’ll guarantee not just efficiency but also the safety of your workspace, allowing you to work with the freedom of knowing your machinery parts are securely hung.

Installation Tips for Heavy-Duty Hooks

When installing heavy-duty hooks, it is vital to confirm that they are anchored securely to support the intended load. Proper hook placement techniques are fundamental for maximizing stability and strength. Use the right installation tools to guarantee a safe and efficient setup. Here are some tips:

- Choose the appropriate wall type for your hooks.

- Use anchors designed for the weight capacity of your load.

- Measure and mark the desired hook placement accurately.

- Tighten all fasteners securely to prevent any movement.

Safety Features to Look For

While evaluating heavy-duty hooks for hanging machinery parts, it is vital to prioritize safety features that guarantee reliability and prevent accidents. Look for hooks that comply with recognized safety standards, ensuring they’ve been designed and tested to handle significant loads. Check if the hooks undergo rigorous load testing to verify their strength and durability under real-world conditions. Features like locking mechanisms can also enhance safety by preventing accidental disengagement. Additionally, consider the material used; high-grade steel offers better resistance to deformation. It is important to assess the weight capacity of each hook, ensuring it aligns with the specific machinery parts you plan to hang. Prioritizing these safety features will provide peace of mind and enhance operational efficiency.

Best Practices for Organizing Your Workspace

Effective workspace organization is essential for enhancing productivity and ensuring safety in environments that involve heavy machinery. A well-thought-out workspace layout can greatly influence your efficiency. Here are some best practices to reflect upon:

- Utilize vertical space for efficient storage, using heavy-duty hooks and shelving.

- Clearly label storage areas to streamline retrieval and reduce downtime.

- Keep frequently used tools and parts within arm’s reach to minimize unnecessary movement.

- Regularly assess your organization system to adapt to changing needs and improve workflow.

Maintenance and Care for Heavy-Duty Hooks

Regular maintenance and care of heavy-duty hooks are essential for ensuring their longevity and reliability in a workspace. To begin, perform routine hook inspections at least once a month, checking for signs of wear, corrosion, or deformation. If any issues arise, replace the hooks immediately to prevent failures. For effective hook cleaning, use a mild detergent and a soft brush to remove dirt and grime, ensuring you don’t damage the surface. Rinse thoroughly and allow them to dry completely before reusing. Additionally, lubricate moving parts with a suitable lubricant to maintain functionality. By prioritizing these maintenance practices, you’ll enhance the performance and lifespan of your heavy-duty hooks, keeping your workspace safe and efficient.

Where to Buy Heavy-Duty Hooks

When you’re ready to purchase heavy-duty hooks, online retailers and local hardware stores offer a variety of options. Online platforms often provide detailed specifications and customer reviews, making it easier to compare products. Conversely, local stores allow you to physically inspect the hooks, ensuring they meet your specific needs.

Online Retailers Overview

Finding the right heavy-duty hooks for hanging machinery parts is essential for ensuring safety and efficiency in your workspace. Online shopping provides a convenient avenue to explore various options and make informed product comparisons. Here are some reliable retailers where you can find quality hooks:

- Amazon: A vast selection with customer reviews to guide your choices.

- eBay: Often features competitive pricing and second-hand options.

- Home Depot: Offers a range of heavy-duty hooks with in-depth product specifications.

- Grainger: Known for industrial-grade products and bulk purchasing options.

Local Hardware Stores

While online retailers offer a wide array of heavy-duty hooks, local hardware stores provide the advantage of immediate access and hands-on inspection. When you visit a local supplier, you can evaluate the material quality, weight capacity, and design options firsthand, ensuring the hooks meet your specific needs. Local stores often stock a variety of purchase options, from standard models to specialized hooks designed for unique machinery parts. Additionally, knowledgeable staff can offer advice on the best choices for your applications, enhancing your buying experience. By choosing to shop locally, you not only support your community but also gain the freedom to make informed decisions based on direct product interaction, optimizing your machinery organization efforts effectively.

References

- https://www.osha.gov/SLTC/etools/pulley/hoisting.html

- https://www.nist.gov/news-events/news/2020/01/choosing-right-hoist-hanging-heavier-weights

- https://www.iaei.org/magazine/2013/06/hanging-it-all-how-to-use-hangers-and-anchors/

- https://www.sciencedirect.com/science/article/pii/S2351978918303399

- https://www.cdc.gov/niosh/topics/falls/default.html

- https://www.liftandhoist.com/2021/04/06/understanding-the-importance-of-hanging-safety/