Hanging Hooks for Airport Maintenance Equipment

Hanging hooks are essential for organizing airport maintenance equipment, ensuring efficient workspace utilization and enhancing safety. They come in various types to accommodate different loads, from heavy-duty steel hooks for heavy equipment to lighter plastic options. Proper installation and strategic placement optimize accessibility while minimizing clutter and hazards. By implementing hanging hooks, you’ll notice improvements in productivity and safety protocols. Explore the diverse options and best practices to maximize your airport maintenance operations effectively.

Importance of Organization in Airport Maintenance

Efficiency is paramount in airport maintenance, where the stakes are high and precision is non-negotiable. An organized approach enables you to maintain an efficient workflow that minimizes downtime and maximizes productivity. By implementing a structured system for tool and equipment storage, you create streamlined operations that reduce the time spent searching for necessary items. Utilizing hanging hooks for various maintenance equipment guarantees everything is accessible yet out of the way, enhancing safety and reducing clutter. This method not only optimizes the workspace but also fosters a culture of responsibility among your team. When every tool has its place, you empower yourself and your colleagues to respond swiftly to any maintenance challenge, ultimately keeping airport operations running smoothly.

Types of Hanging Hooks for Various Equipment

When it comes to hanging hooks for airport maintenance equipment, understanding the different types available is essential. You’ll find heavy-duty hooks designed for substantial loads, adjustable options that offer versatility, and specialized hooks tailored for specific equipment. Each type plays a significant role in ensuring safety and efficiency in your maintenance operations.

Heavy-Duty Hooks Overview

Heavy-duty hooks play an essential role in organizing and securing airport maintenance equipment, ensuring that tools are readily accessible and safely stored. These hooks are crafted from heavy-duty materials, designed to withstand rigorous use and environmental conditions. With various types available, you can select hooks that offer specific load capacities tailored to your equipment needs. For instance, some hooks can support substantial weights, making them ideal for larger tools and equipment. When choosing the right heavy-duty hooks, consider factors like material strength, corrosion resistance, and the intended application. By utilizing the appropriate hooks, you can maintain an organized workspace, enhancing efficiency and safety in your airport maintenance operations.

Adjustable Hook Options

Selecting the right adjustable hook options can greatly enhance the organization of airport maintenance equipment. These hooks come with adjustable weight capacities, allowing you to safely store various equipment without compromising safety. You can choose hooks that feature customizable lengths, ensuring they fit perfectly in your storage space while accommodating different tools. For instance, if you’re hanging lighter items, opt for hooks with lower adjustable weights, and for heavier tools, select those designed to handle greater loads. This flexibility not only maximizes your available space but also simplifies access to your gear. By implementing adjustable hooks, you’ll enjoy a more organized workspace, allowing you the freedom to focus on maintaining airport operations efficiently.

Specialized Equipment Hooks

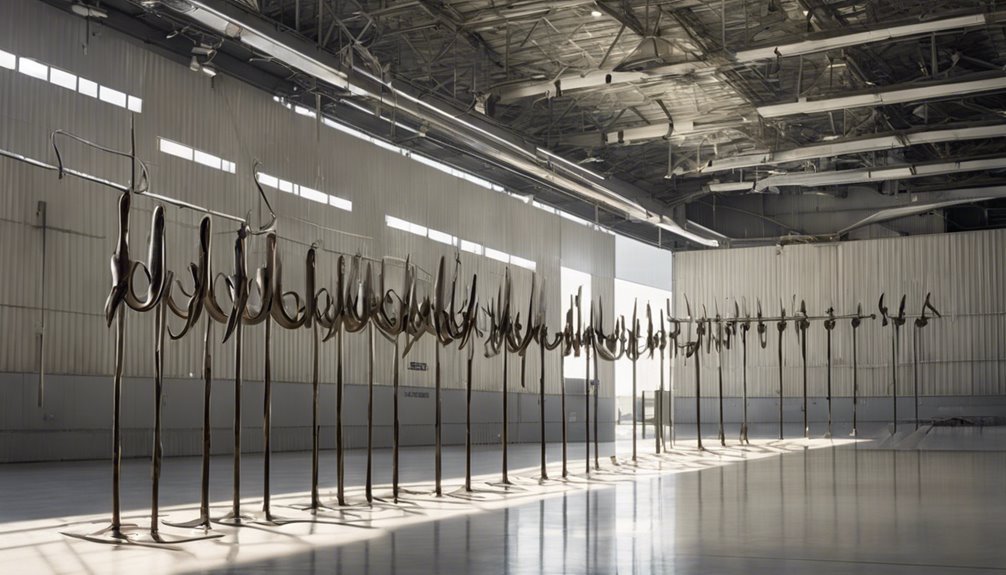

While maintaining airport facilities, using specialized equipment hooks can greatly streamline your operations by providing tailored solutions for hanging various tools and gear. These hooks come in various designs, each engineered for specific equipment types, ensuring ideal specialized storage. For instance, heavy-duty hooks can support items like ladders and power tools, while lighter hooks are perfect for hand tools or safety gear. By implementing these specialized hooks, you enhance equipment accessibility, allowing your team to quickly retrieve the tools they need without clutter. Furthermore, these hooks can be integrated into existing storage systems, maximizing vertical space in hangars or maintenance areas. Investing in specialized equipment hooks not only improves organization but also boosts efficiency, ultimately contributing to smoother airport operations.

Benefits of Using Hanging Hooks

Utilizing hanging hooks for airport maintenance equipment offers significant advantages that enhance both efficiency and safety. First, these hooks maximize space efficiency, allowing you to organize tools and equipment vertically. This not only frees up valuable floor space but also makes it easier for your team to access necessary items quickly, reducing downtime. Furthermore, hanging equipment can contribute to equipment longevity by minimizing wear and tear associated with improper storage. By keeping tools off the ground and away from potential hazards, you can extend their lifespan and maintain operational readiness. Ultimately, adopting hanging hooks creates a more streamlined workflow, empowering your maintenance staff to perform their tasks with greater freedom and effectiveness.

How to Choose the Right Hanging Hooks

Choosing the right hanging hooks is fundamental to maximizing the benefits of efficient equipment storage in airport maintenance. You’ll want to take into account hook materials and weight capacity to guarantee they meet your specific needs. Here’s a quick guide to help you:

| Hook Material | Weight Capacity | Use Case |

|---|---|---|

| Steel | Up to 200 lbs | Heavy equipment |

| Aluminum | Up to 150 lbs | Medium equipment |

| Plastic | Up to 50 lbs | Light tools |

| Stainless Steel | Up to 300 lbs | Corrosive environments |

| Composite | Up to 100 lbs | Versatile applications |

Evaluate these options based on durability and intended use. Selecting the right hooks not only enhances safety but also streamlines your workflow, giving you the freedom to focus on maintenance tasks.

Installation Tips for Optimal Use

To guarantee ideal use of hanging hooks for airport maintenance equipment, proper installation is essential. Start by identifying the best placement for your hooks; consider the weight and frequency of use of the equipment. Use sturdy wall anchors and verify your hooks are securely fastened to withstand heavy loads. Employ installation techniques like measuring the distance between hooks to avoid overcrowding, allowing easy access and minimizing potential hazards. It’s also vital to maintain a height that suits your workflow, preventing unnecessary strain during retrieval. Regularly check the integrity of the hooks and surrounding structure to confirm continued safety and functionality. By following these guidelines, you’ll maximize efficiency and maintain the freedom in your operations.

Enhancing Safety With Proper Equipment Storage

While proper installation of hanging hooks is essential, enhancing safety with effective equipment storage is equally important. By adhering to safety protocols, you guarantee that equipment is stored securely, minimizing the risk of accidents. Start by evaluating the specific hanging hooks needed for your equipment’s weight and size, ensuring they can handle the load without compromising equipment durability. Organize your storage area to allow easy access while preventing overcrowding, which can lead to potential hazards. Regularly inspect both the hooks and the equipment for signs of wear and tear, as this proactive approach can prevent failures. Implementing these strategies not only promotes a safer work environment but also extends the lifespan of your maintenance equipment, providing peace of mind as you work.

Case Studies: Success Stories From Airports Using Hanging Hooks

In examining case studies from various airports, you’ll notice that the implementation of hanging hooks greatly enhances organization strategies. These systems not only streamline equipment storage but also lead to improved safety outcomes by minimizing hazards associated with clutter. By analyzing these success stories, you can gain insights into effective practices that could be applied to your own maintenance operations.

Enhanced Organization Strategies

As airports increasingly prioritize efficiency and safety, implementing enhanced organization strategies through hanging hooks has proven transformative. By optimizing space and ensuring that tools are easily accessible, you’ll find that inventory management becomes markedly more effective. Case studies reveal that airports have successfully reduced clutter and improved workflow, allowing maintenance teams to focus on critical tasks without the distraction of disorganized equipment. For instance, a major airport reported a 30% increase in productivity after integrating hanging hooks, leading to faster response times for equipment retrieval. This approach not only maximizes available space but also fosters a culture of accountability and order. Embracing these strategies can empower your team to operate efficiently, enhancing overall airport operations.

Improved Safety Outcomes

By integrating hanging hooks into maintenance operations, airports have reported significant improvements in safety outcomes, showcasing the tangible benefits of this organizational strategy. Case studies reveal that implementing these hooks has led to better adherence to safety protocols. For instance, one airport observed a 30% reduction in equipment-related accidents after adopting a structured hanging system.

These hooks facilitate effective risk assessment by ensuring tools and equipment are stored in designated areas, minimizing trip hazards and promoting a clutter-free environment. Additionally, maintenance teams can quickly access necessary tools without searching through piles of equipment, reducing the likelihood of mishaps. Overall, the use of hanging hooks not only enhances efficiency but also fosters a culture of safety, giving personnel the freedom to focus on critical tasks.