Best Hooks for Securing Spacecraft Cargo

When securing spacecraft cargo, consider using carabiner hooks for their lightweight strength, or snap hooks for corrosion resistance. S-hooks work well for lighter loads, while swivel hooks help reduce twisting in dynamic situations. For heavier cargo, over-center hooks provide robust reliability. Verify your chosen hooks meet load capacity, material durability, and temperature stability to optimize safety. There are innovative technologies enhancing cargo security, and exploring these advancements can further improve your mission efficiency.

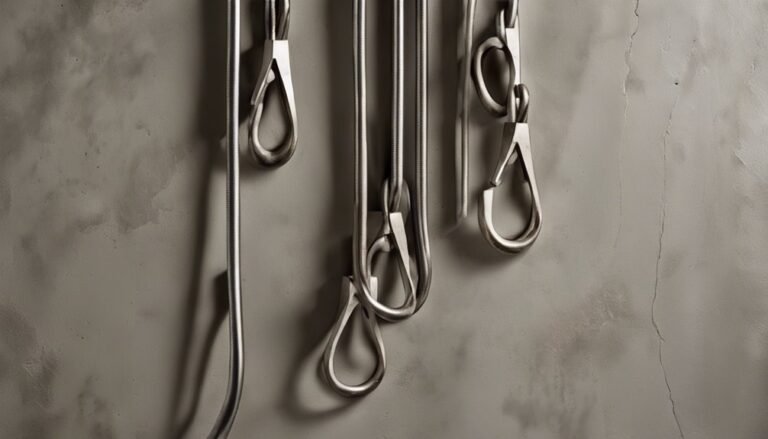

Overview of Spacecraft Cargo Hooks

When it comes to securing cargo in spacecraft, understanding the functionality and design of cargo hooks is essential. These hooks play a critical role in ensuring cargo safety during launch, travel, and landing. Analyzing the materials used in hook construction is crucial; they must withstand extreme conditions, including temperature variations and mechanical stresses. Typically, high-strength alloys or composite materials are favored for their durability and lightweight properties. The design of these hooks often incorporates mechanisms that allow for quick and secure attachment, minimizing the risk of cargo movement. By focusing on the right hook materials and understanding their operational mechanics, you can optimize cargo safety, ensuring that the payload remains secure throughout the mission.

Types of Hooks Used in Space Missions

Cargo hooks in space missions come in various designs, each tailored to specific operational needs. You’ll find hooks made from advanced cargo hook materials like titanium and aerospace-grade aluminum, providing both strength and lightweight properties. These materials help guarantee that the hooks can withstand the harsh conditions of space while maintaining their integrity.

The hook load ratings are vital; they dictate the maximum load a hook can safely handle during transport. For example, some hooks are rated for thousands of pounds, accommodating various cargo types. Understanding these specifications allows you to select the right hook for your mission. By choosing the appropriate design and materials, you can enhance safety and efficiency in securing spacecraft cargo.

Key Features to Consider When Choosing Hooks

Selecting the right hooks for securing cargo involves several essential features that can greatly impact safety and efficiency. First, consider the load capacity of the hooks; they must handle the weight of your cargo without risk of failure. Verify that the hooks meet or exceed the required specifications, as underestimating this can lead to catastrophic results. Additionally, material durability is imperative; choose hooks made from high-strength materials that can withstand the harsh conditions of space missions. Corrosion resistance and temperature stability are also important, as they enhance longevity and reliability. By focusing on these key features, you can guarantee that your cargo remains secure, allowing for the freedom to concentrate on your mission’s objectives without unnecessary worry.

Top 5 Hooks for Securing Spacecraft Cargo

While ensuring the safety of your spacecraft’s payload, choosing the right hooks for securing cargo is essential. Here are the top five hooks to evaluate:

- Carabiner Hooks – Made from lightweight aluminum, they offer high strength-to-weight ratios, suitable for varying cargo weights.

- Snap Hooks – These stainless-steel options provide durability and resistance to corrosion, ensuring longevity in space conditions.

- S-Hooks – Ideal for lighter cargo, their simplicity allows for quick adjustments and easy handling.

- Swivel Hooks – With a rotating design, they minimize twisting, perfect for dynamic loads.

- Over-center Hooks – Crafted from robust steel, they secure heavy cargo effectively, making them ideal for high-stress applications.

Each hook type’s material and design cater to specific cargo weight requirements, ensuring secure transport.

Innovations in Hook Technology

As advancements in materials science and engineering progress, new innovations in hook technology are reshaping how payloads are secured in various environments, including space. You’ll find that these developments focus on enhancing efficiency and reliability through superior hook materials and automated fastening systems.

- Lightweight composites: Reducing overall weight without compromising strength.

- Smart hooks: Integrating sensors for real-time load monitoring and adjustments.

- Modular designs: Allowing for easy customization and rapid deployment.

These innovations not only improve cargo security but also streamline the entire loading and unloading process. By adopting these advanced technologies, you can guarantee that your payloads are secured with the highest level of safety and efficiency, reflecting a commitment to freedom in exploration and innovation.

Best Practices for Using Cargo Hooks in Space

With the evolution of hook technology, effectively utilizing cargo hooks in space requires adherence to specific best practices to guarantee safety and reliability. First, always assess the load’s weight distribution. Improper distribution can lead to instability during transport, compromising cargo safety. Make sure that the hooks are appropriately rated for the weight and type of cargo you’re securing. Regularly inspect hooks for wear or damage, as the harsh space environment can affect their integrity. Utilize locking mechanisms to prevent accidental release; this is vital in zero-gravity conditions. Finally, when securing cargo, use a systematic approach, aligning cargo with the spacecraft’s center of gravity to enhance stability. By following these guidelines, you can maximize cargo safety and maintain mission integrity in the vastness of space.

References

- https://en.wikipedia.org/wiki/Cargo_transportation_in_space

- https://www.nasa.gov/mission_pages/station/structure/elements/pressurized_modules.html

- https://www.nasa.gov/sites/default/files/atoms/files/nasa_spacecraft_cargo_management.pdf

- https://www.sciencedirect.com/science/article/pii/S0094576521000187

- https://www.jpl.nasa.gov/news/news.php?feature=7417

- https://www.nasa.gov/centers/jpl/news/spacecraft_cargo.html

- https://www.iaea.org/publications/research-reports/spacecraft-safety-and-evaluation-cargo-transportation

- https://www.nist.gov/publications/spacecraft-cargo-securing-systems

- https://www.esa.int/Applications/Space_Transportation/Space_Cargo